TEL:0755-23309105

ADD: Room 811, Jinfulai Building, 49-1 Dabao Road, Bao'an District, Shenzhen

EMAIL:jxd@elkpure.com

TEL:0755-23309105

ADD: Room 811, Jinfulai Building, 49-1 Dabao Road, Bao'an District, Shenzhen

EMAIL:jxd@elkpure.com

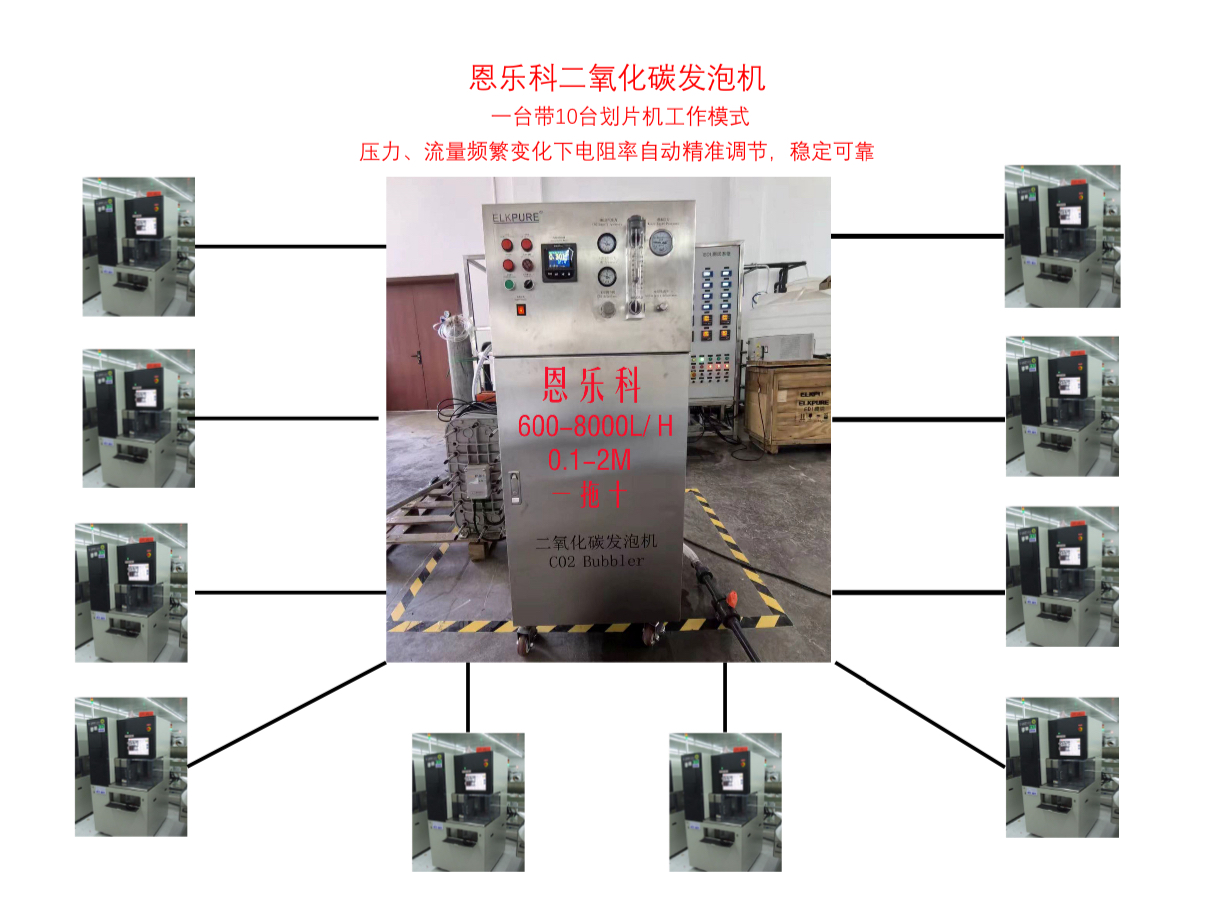

ELKPURE CO2 bubbler,Ultrapure water anti-static device

model:ELK-1000L 、ELK-2000L、ELK-3000L、ELK-4000L、ELK-5000L、ELK-6000L、ELK-7000L、ELK-8000L、ELK-10000L

manufacturer: ELKPURE flow:1000-10000L/H

Manufacturer: carbon dioxide foaming machine, also known as ultrapure water anti-static device, deionized water and electricity resistance regulating device, CO2 bubbler, carbon adding machine。

●Equipment use:

Equipment use CO2 bubbler is to add high-purity carbon dioxide to ultra-pure water with high resistivity, generate an appropriate amount of ions in the water, enhance the conductivity of ultra-pure water, reduce the resistivity of ultra-pure water, prevent electrostatic damage to products during semiconductor processing such as dicing process and cleaning, eliminate the electrostatic adsorption of silicon chips for cleaning, and finally volatilize carbon dioxide after drying without leaving any impurities and causing no secondary pollution.

Carbon dioxide foaming machine can effectively control the electrostatic micro harm in the production process of microelectronics industry, prevent the product from being damaged due to electrostatic discharge due to electrostatic adsorption, prevent electrostatic damage and particle adhesion, greatly improve the product yield and reduce the production cost.

●Equipment principle:

he design principle is to realize the clean CO2 dye-free injection of ultra pure water through membrane contactor. The characteristic of membrane contactor is that gas can be dialytically dissolved into water evenly through the membrane surface, while water and particulate impurities are difficult to penetrate the membrane. This special membrane is used to separate CO2 gas from ultra pure water. The dissolution amount of CO2 in water can be controlled through the precision adjustment device in the equipment, so as to accurately control the resistivity of water. The resistivity of product water can be easily and accurately adjusted to 0.1-2m Ω· cm.

●Equipment characteristics:

Equipment features: the equipment is simple to operate, easy to use and low in failure rate. It uses water-proof gas membrane to inject CO2 without bubbles. In addition, it basically does not waste C02 except that it needs to discharge the CO2 carried out by the exhaust gas for 1 second every 1 hour. The resistivity of product water can be easily and accurately adjusted to the range of 0.1-2m Ω· cm. When the water flow changes, the variation range of resistivity can be controlled within ± 0.1M Ω· cm. The equipment is made of clean materials that meet the requirements of semiconductor ultra pure water to avoid secondary pollution. The chassis is made of mirror stainless steel, which is applicable to the requirements of class 100 purification workshop.

●Applicable industries:

This equipment is necessary for semiconductor manufacturing, FPD Manufacturing, silicon wafer and chip cutting processes.

High purity CO2 injection can neutralize alkaline residues and make pure water weakly acidic, which is suitable for silicon wafer BEOL cleaning process. Semiconductor material cleaning.