TEL:0755-23309105

ADD: Room 811, Jinfulai Building, 49-1 Dabao Road, Bao'an District, Shenzhen

EMAIL:jxd@elkpure.com

TEL:0755-23309105

ADD: Room 811, Jinfulai Building, 49-1 Dabao Road, Bao'an District, Shenzhen

EMAIL:jxd@elkpure.com

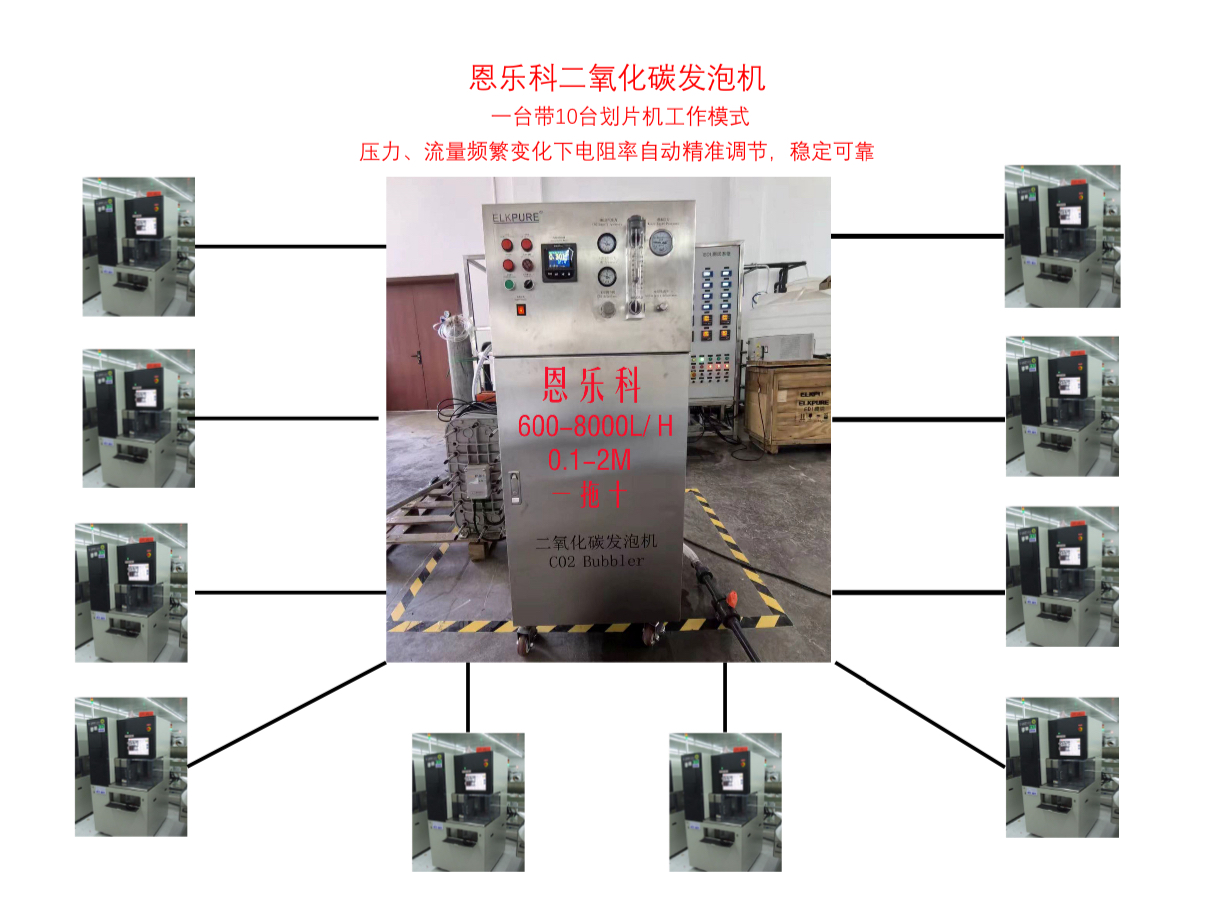

CO2 bubbler ELK-8000L , ELKPURE CO2 bubbler CO2 foaming machine ELK-8000L ultrapure water anti-static device is used for semiconductor wafer dicing, cleaning to eliminate product static electricity and prevent product static damage. The method of 1 drag 10 can be adopted, which greatly reduces the cost of users.Flow rate 600-8000L/H

The ELK-8000L ultra pure water anti-static device of the Enrico CO2 bubbler carbon dioxide foaming machine is used for semiconductor wafer slicing, cleaning and eliminating product static electricity to prevent product static damage. A 1-to-10 working mode can be adopted, greatly reducing user costs.

Product Features:

Carbon dioxide foaming machine, also known as CO2 bubbler (ultra pure water anti-static device, carbon dioxide bubbling machine), deionized water resistance adjustment device, carbon addition machine, etc. The principle is to add high-purity carbon dioxide to high resistivity pure water, generate an appropriate amount of ions in the water to enhance the conductivity of pure water, reduce the resistivity of pure water, prevent static electricity damage to products during semiconductor and TFT processing such as wafer slicing and chip cleaning, eliminate the static adsorption of silicon chips for easy cleaning, and finally, after drying, the carbon dioxide evaporates without leaving any impurities, without causing secondary pollution. Ultra pure water anti-static devices and equipment can effectively control the static hazards in the production process of microelectronics industry, prevent static adsorption from causing damage to products due to electrostatic discharge, prevent static damage and surface adhesion of particles, greatly improve product yield and reduce production costs.

Equipment principle:

After years of research and testing, our company produces the ELK series ultra pure water anti-static device. All of this device uses imported high-quality materials and instruments, and the design principle is to achieve clean CO2 injection of ultra pure water without pollution through membrane contactors. The characteristic of membrane contactor is that gas can be dialyzed through the membrane surface and uniformly dissolved into water, while water and particulate impurities are difficult to penetrate the membrane. By using this special membrane to separate CO2 gas from ultrapure water, the precise adjustment device in the equipment can control the amount of CO2 dissolved in water, thereby achieving precise control of water resistivity. The electrical resistivity of product water can be easily and accurately adjusted within the range of 0.1-2M Ω• cm. This product can eliminate the hazards caused by static electricity generated on the surface of the product, such as electrostatic adsorption pollution and electrostatic discharge damage, greatly improving the yield rate of the product. This product is widely used in the microelectronics and semiconductor industries.

Equipment features:

1. All materials use pure water pipe fittings and instruments

2. The device has a simple and compact structure, occupies less space, and is easy to install

3. Zero delay response to flow changes, ensuring high stability of water production resistivity

4. Gas saving, low power consumption, low CO2 consumption, energy-saving and environmentally friendly

5. Accurate and stable control of resistivity values under extremely low water flow conditions

6. Fully self operated adaptive mixing method, the electrical resistivity of the product water can be easily and accurately adjusted to the range of 0.1-2M Ω• cm

7. Pure mechanical static operation with extremely low failure rate

8. Adopting the most advanced breathable membrane method without air infiltration, the quality of the produced water completely surpasses similar products

9. Support one to many mode, precise and stable control of resistivity values under flow and pressure changes of 10-8000L/H

10. Has data and signal transmission and storage functions

model:

Flow range: 10-8000L/H

Applicable industries:

1. Microcircuit chip cutting and cleaning 2, photomask cutting and cleaning 3, wafer cutting and chip cleaning 4, semiconductor silicon wafer cutting and cleaning

5. Cutting and cleaning of solar cells 6. Cutting and cleaning of TFT panels 7. Control of ultra pure water resistors for special industries 8. Optical lenses and headphones